硬质合金钻头制造商

“高效服务,提升您的生产力 我们深知时间对您的业务的重要性。通过优化流程和提供高效服务,我们帮助客户在最短的时间内实现生产力最大化。我们的团队确保及时交付项目,让您专注于核心业务。”

JINOO 精诺

整体硬质合金麻花钻是设计用于在工件上制造精确圆孔的切削工具。

整体硬质合金螺旋钻头采用紧凑设计,具有螺旋切削刃,有助于分散切削力,减少工件应力并延长刀具寿命。其先进的设计和切削几何形状可确保更顺畅的钻孔过程,从而在材料上钻出精确的圆形孔。

硬质合金钻头生产工艺

钻头参数

针对不同的孔尺寸和深度,钻头有不同的直径。

较小直径的钻头通常被使用,并且有各种长度,例如 3D、5D 和 8D。其特点包括宽容槽,以便更好地排出切屑,以及波纹刀片,以便高效断屑。

- 小型硬质合金钻头-直径1-2.9mm

直径为 1 毫米至 2.9 毫米的硬质合金钻头是专为精确钻小孔而设计的精密工具。它们由高品质硬质合金制成,具有出色的硬度、耐磨性和耐用性。

- 微硬质合金钻头3d -直径1-20mm

- 微硬质合金钻头5d -直径1-20mm

- 微硬质合金钻头8d -直径3-20mm

8D 微直径钻头是其直径的八倍,专为航空航天部件和医疗设备中的微孔组件等应用中的深孔钻孔而设计。

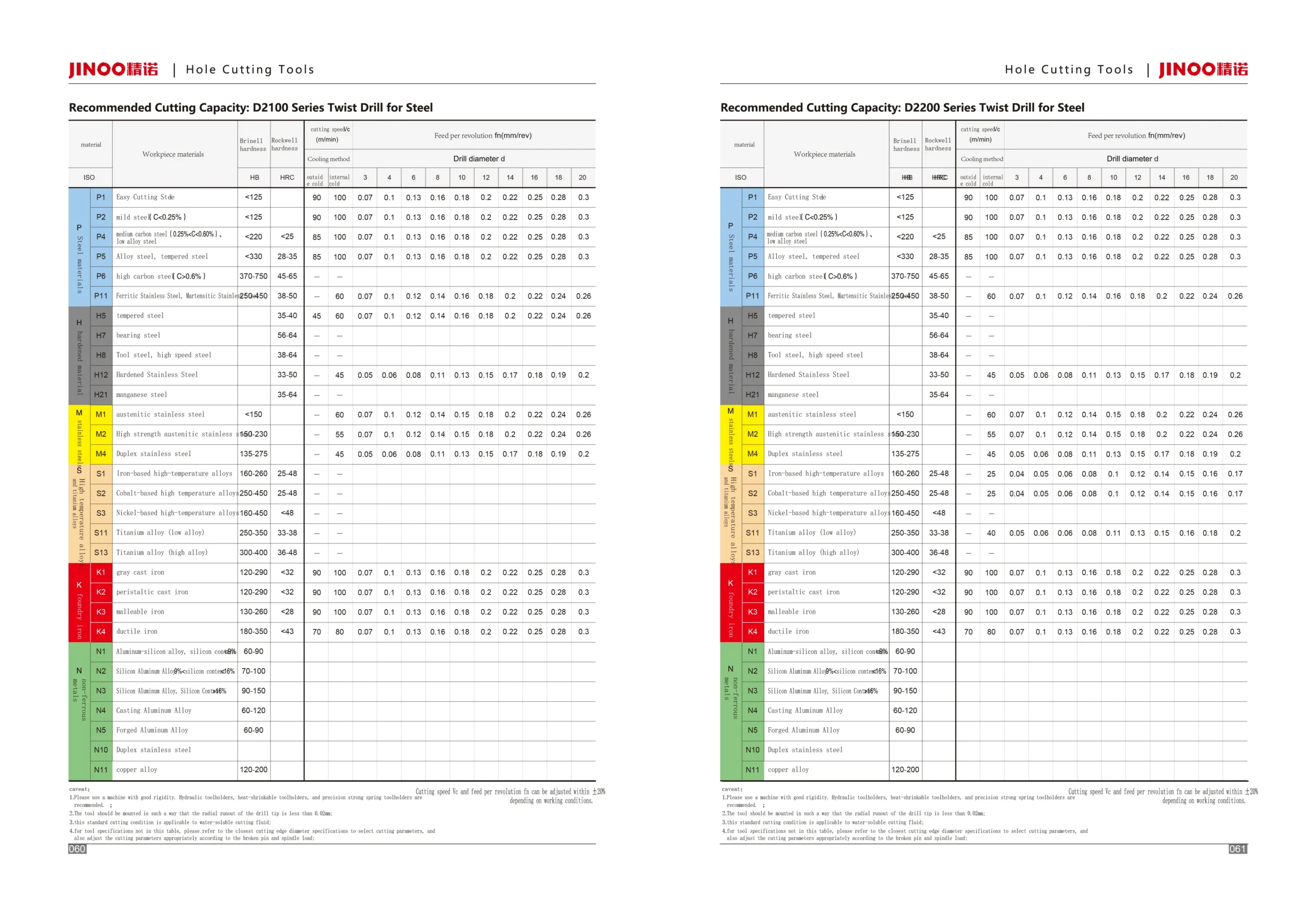

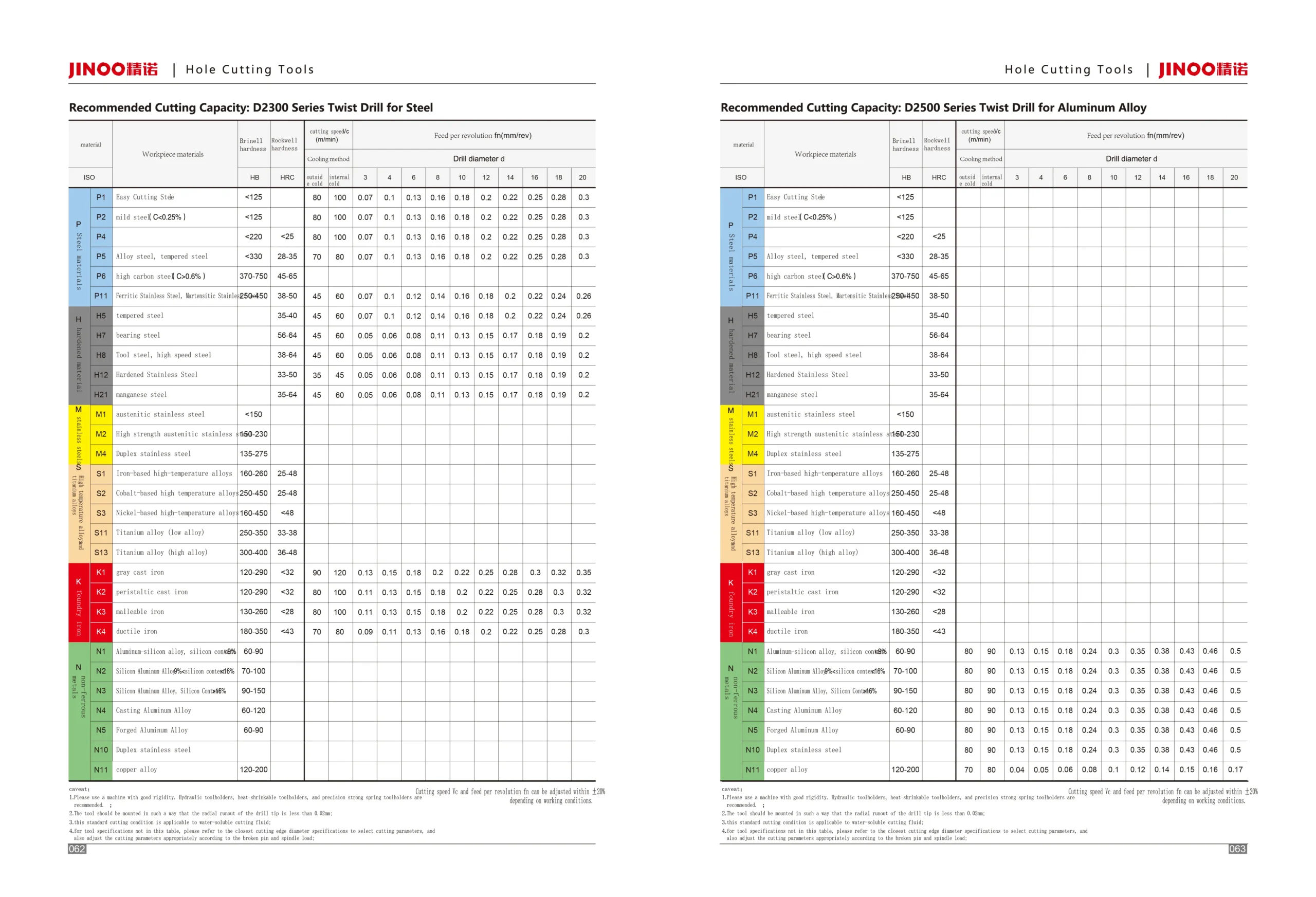

相应的加工范围表

加工范围对应表 | |||||||||||||||||||||||||||||

P (钢材) | H (硬化材料) | M (不锈钢) | S (高温合金和钛合金) | K (铸铁) | N(有色金属) | ||||||||||||||||||||||||

P1 | P2 | P4 | P5 | P6 | P11 | H3 | H5 | H7 | H8 | H12 | H21 | M1 | M2 | M4 | S1 | S2 | S3 | S11 | 问题 1 | K2 | K3 | K4 | N1 | 氮气 | N3 | N4 | N5 | N10 | N11 |

● |

| ● | ● |

| ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● |

|

|

|

|

|

|

|

● | ● | ● | ● |

| ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● |

|

|

|

|

|

|

|

● | ● | ● | ● |

| ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● |

|

|

|

|

|

|

|

● | ● | ● | ● |

| ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● |

|

|

|

|

|

|

|

● | ● | ● | ● |

| ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● |

|

|

|

|

| ○ | ○ |

● | ● | ● | ● |

| ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● |

|

|

|

|

| ○ | ○ |

● | ● | ● | ● |

| ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● |

|

|

|

|

| ○ | ○ |

● | ● | ● | ● |

| ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● |

|

|

|

|

| ○ | ○ |

○ | ○ |

|

|

| ○ |

|

|

|

| ○ |

| ● | ● | ● | ● | ● | ● | ● |

|

|

|

|

|

|

|

|

| ○ | ○ |

○ | ○ |

|

|

| ○ |

|

|

|

| ○ |

| ● | ● | ● | ● | ● | ● | ● |

|

|

|

|

|

|

|

|

| ○ | ○ |

○ | ○ | ● | ● | ● | ● |

| ● |

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● |

|

| ○ | ○ | ○ |

|

|

○ | ○ | ● | ● | ● | ● |

| ● |

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● |

|

| ○ | ○ | ○ |

|

|

○ | ○ | ● | ● | ● | ● |

| ● |

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● |

|

| ○ | ○ | ○ |

|

|

○ | ○ | ● | ● | ● | ● |

| ● |

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● |

|

| ○ | ○ | ○ |

|

|

○ | ○ | ● | ● | ● | ● |

| ● |

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● |

|

| ○ | ○ | ○ |

|

|

○ | ○ | ● | ● | ● | ● |

| ● |

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● |

|

| ○ | ○ | ○ |

|

|

- 最适应

- 适应

加工范围对应表 | |||||||||||||||||||||||||||||

P (钢材) | H (硬化材料) | M (不锈钢) | S (高温合金和钛合金) | K (铸铁) | N (有色金属) | ||||||||||||||||||||||||

P1 | P2 | P4 | P5 | P6 | P11 | H3 | H5 | H7 | H8 | H12 | H21 | M1 | M2 | M4 | S1 | S2 | S3 | S11 | Q1 | K2 | K3 | K4 | N1 | 氮气 | N3 | N4 | N5 | N10 | N11 |

● | ● | ● | ● | ● | ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

● | ● | ● | ● | ● | ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

● | ● | ● | ● | ● | ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

● | ● | ● | ● | ● | ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

● | ● | ● | ● | ● | ○ |

| ○ |

|

| ○ |

| ○ | ○ | ○ |

|

|

|

| ● | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● | ● | ● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● | ● | ● |

|

● | ● | ● | ● | ● | ○ |

| ○ |

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

|

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ○ | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ○ | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

|

- 最适应

- 适应

开孔工具

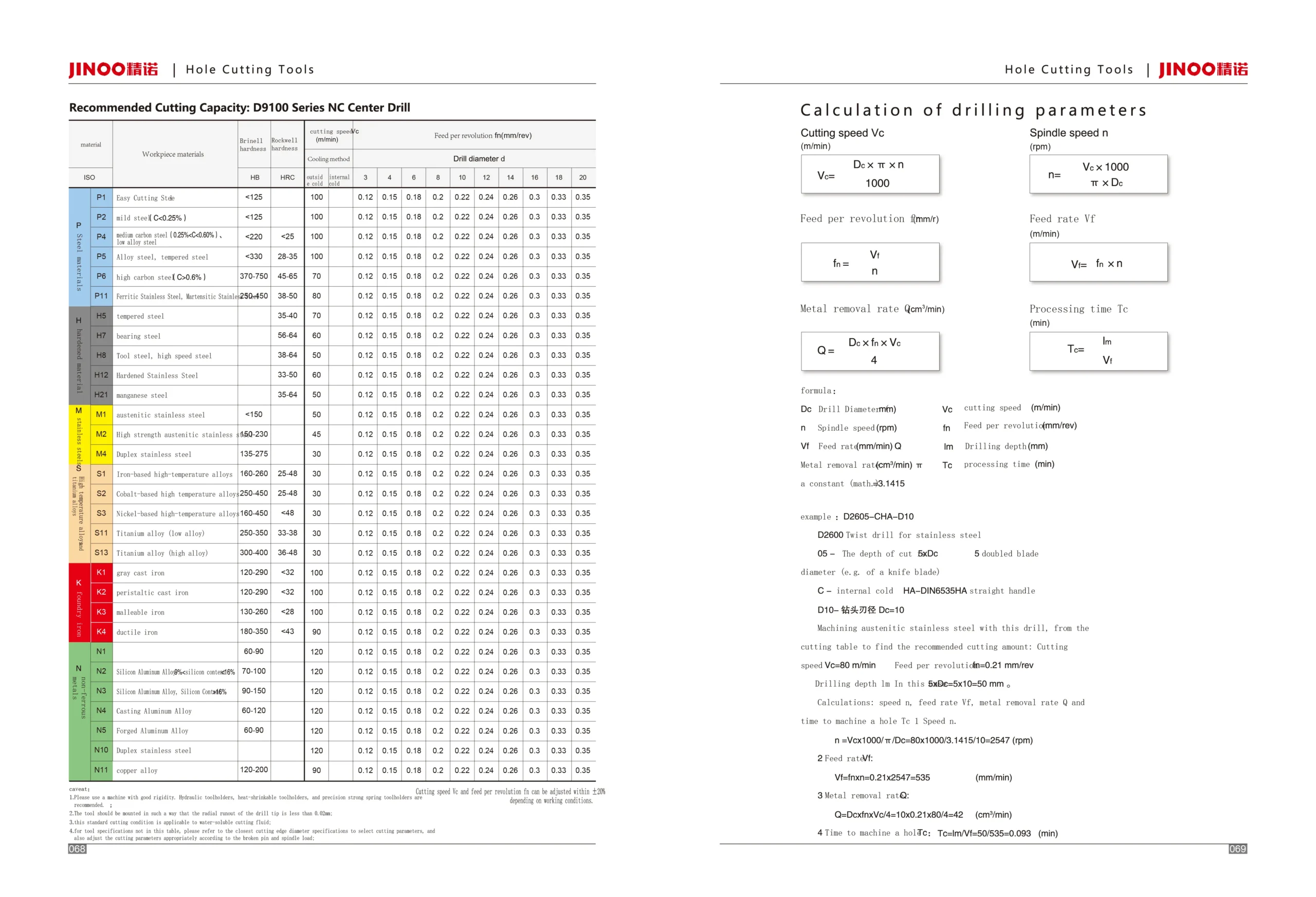

Drill Coding Rules:

D | 26 | 05 | – | C | HA | – | 0800 | ||||||

⑴ | ⑵ | ⑶ |

| ⑷ | ⑸ |

| ⑹ | ||||||

⑴ | – | Product Category |

| D | Drill Bits | ||||||||

⑵ | – | Product Series |

| 21 | Twist drills for steel | ||||||||

| 22 | Twist drills for steel | |||||||||||

23 | Twist drills for steel | ||||||||||||

25 | Twist drills for aluminium | ||||||||||||

26 | Twist drills for stainless steel | ||||||||||||

30 | Deep Hole Twist Drills | ||||||||||||

52 | Three-flute drills | ||||||||||||

72 | Straight Groove Drill | ||||||||||||

91 | NC Centre Drill | ||||||||||||

⑶ | – | Depth of Cut |

| 00 | Centre Drill | ||||||||

| 03 | 3xd | |||||||||||

05 | 5xd | ||||||||||||

08 | 8xd | ||||||||||||

20 | 20xd | ||||||||||||

⑷ | – | Cooling Method |

| N | External Coolant | ||||||||

| C | Internal Coolant | |||||||||||

⑸ | – | Shank Form |

| HA | DIN6535HA | ||||||||

| HB | DIN6535HB | |||||||||||

HE | DIN6535HE | ||||||||||||

YZ | Plain Cylindrical Shank | ||||||||||||

⑹ | – | Blade Diameter |

| 0050 | 0.5mm | ||||||||

| 0100 | 1mm | |||||||||||

0800 | 8mm | ||||||||||||

1000 | 10mm | ||||||||||||

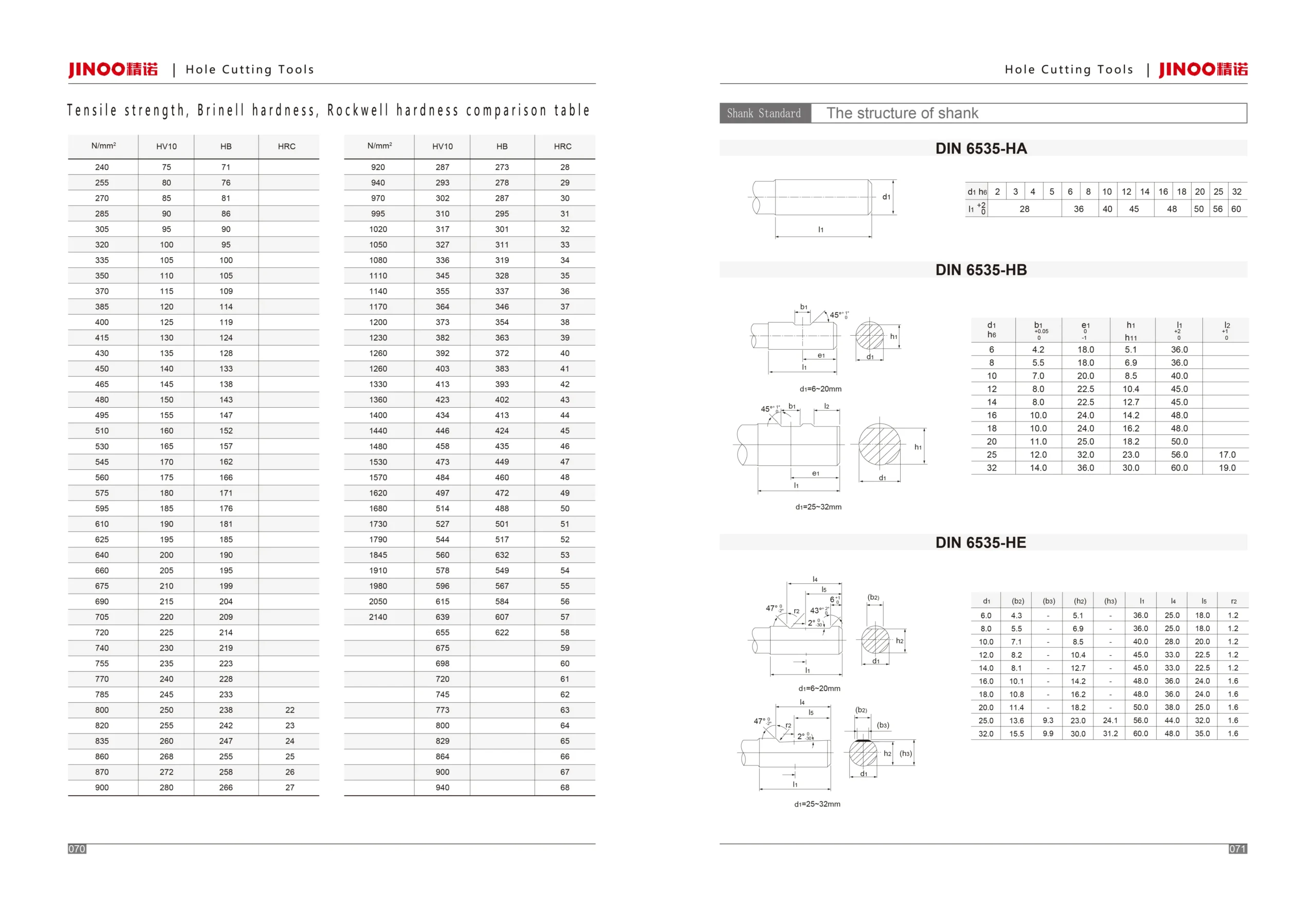

Workpiece Material Table:

Material Group ISO |

Workpiece Materials |

Quantity Contained |

Tensile Strength |

Brinell Hardness |

Rockwell Hardness | |

|

| N / m m 2 | HB | HRC | ||

P Material of Steel Parts | P1 | Easy Cutting Steels |

| < 320 | < 125 |

|

P2 | Low Carbon Steel | C < 0.25% | 320-530 | < 125 |

| |

P4 | Medium Carbon Steels, Low Alloy Steels | 0.25% < C < 0.60% | 520-850 | < 220 | < 25 | |

P5 | Alloy Steel, Tempered Steel |

| 550-1200 | < 330 | 28-35 | |

P6 | High Carbon Steel | C > 0.6% | 600-1200 | 370-750 | 45-65 | |

P11 | Ferritic Stainless Steel, Martensitic Stainless Steel |

| 600-1350 | 250-450 | 38-50 | |

H Hardened Material | H3 | Surface Hardened Steel |

| 800-1500 |

| 58-62 |

H5 | Tempered Steel |

| 490-1200 |

| 35-56 | |

H7 | Bearing Steel |

| 900-1600 |

| 56-64 | |

H8 | Tool Steels, High Speed Steels |

|

|

| 60-64 | |

H12 | Hardened Stainless Steels |

|

|

| 33-50 | |

H21 | Manganese Steels |

|

|

| 35-64 | |

M Stainless Steels | M1 | Austenitic Stainless Steel |

| 600-1100 | < 150 |

|

M2 | High Strength Austenitic Stainless Steels |

| 1100-1750 | 150-230 |

| |

M4 | Duplex Stainless Steels |

| 600-1300 | 230-310 |

| |

S High Temperature Alloys and Titanium Alloys | S1 | Iron-Based High Temperature Alloys |

| 500-1200 | 160-260 | 25-48 |

S2 | Cobalt-Based High Temperature Alloys |

| 1000-1450 | 250-450 | 25-48 | |

S3 | Nickel-Based High Temperature Alloys |

| 600-1700 | 160-450 | < 48 | |

S11 | Titanium Alloys |

| 900-1600 | 300-400 | 33-38 | |

K Foundry Iron | K1 | Grey Cast Iron |

| 130-340 | 110-270 | < 32 |

K2 | Peristaltic Cast Iron |

| 300-570 | 120-290 | < 32 | |

K3 | Malleable Iron |

| 200-530 | 150-290 | < 28 | |

K4 | Ductile Cast Iron |

| 400-900 | 180-350 | < 43 | |

N Non-Ferrous Metals (All Metals Excluding Iron, Chromium, Manganeseand their Alloys) | N1 | Aluminium-Silicon Alloys | Silicon Content <9 Percent | < 200 | 60-90 |

|

N2 | Silicon Aluminium Alloys | 9%<Silicon Content<16% | 200-300 | 70-100 |

| |

N3 | High Silicon Aluminium Alloys | Silicon Content >16 Percent | 200-350 | 90-150 |

| |

N4 | Casting Aluminium Alloy |

| 155-460 | 45-100 |

| |

N5 | Forged Aluminium Alloys |

|

| 60-90 |

| |

N10 | Copper |

| 20-30 | 35-45 |

| |

N11 | Copper Alloy |

|

| 120-200 |

| |